Author: Dr. Augusto César Bessa Neves

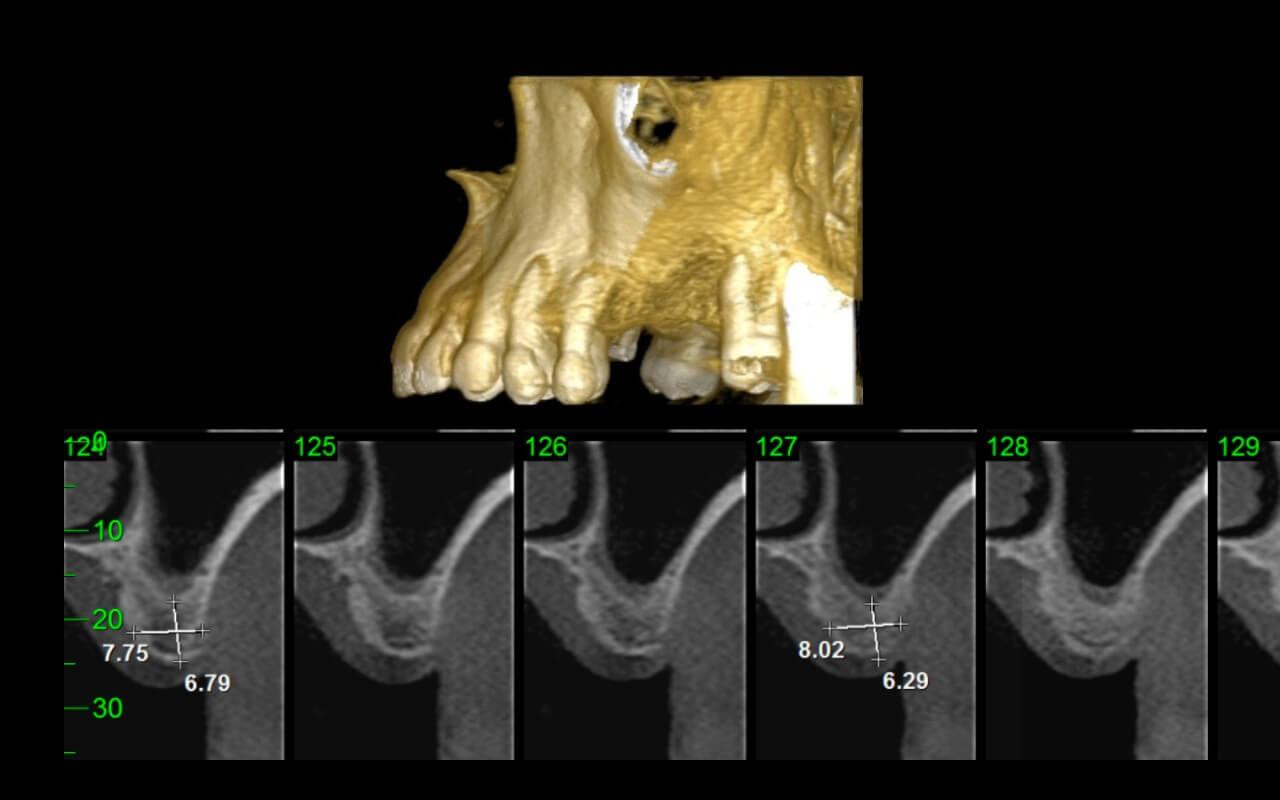

40-year-old male patient, dissatisfaction with the absence of elements 26 and 27.

Initial evaluation

After detailed anamnesis, clinical and radiographic examination, the absence of elements 26 and 27 was noted, and, it was also noted that topographically, there was a pneumatization of the maxillary sinus floor.

Treatment carried out

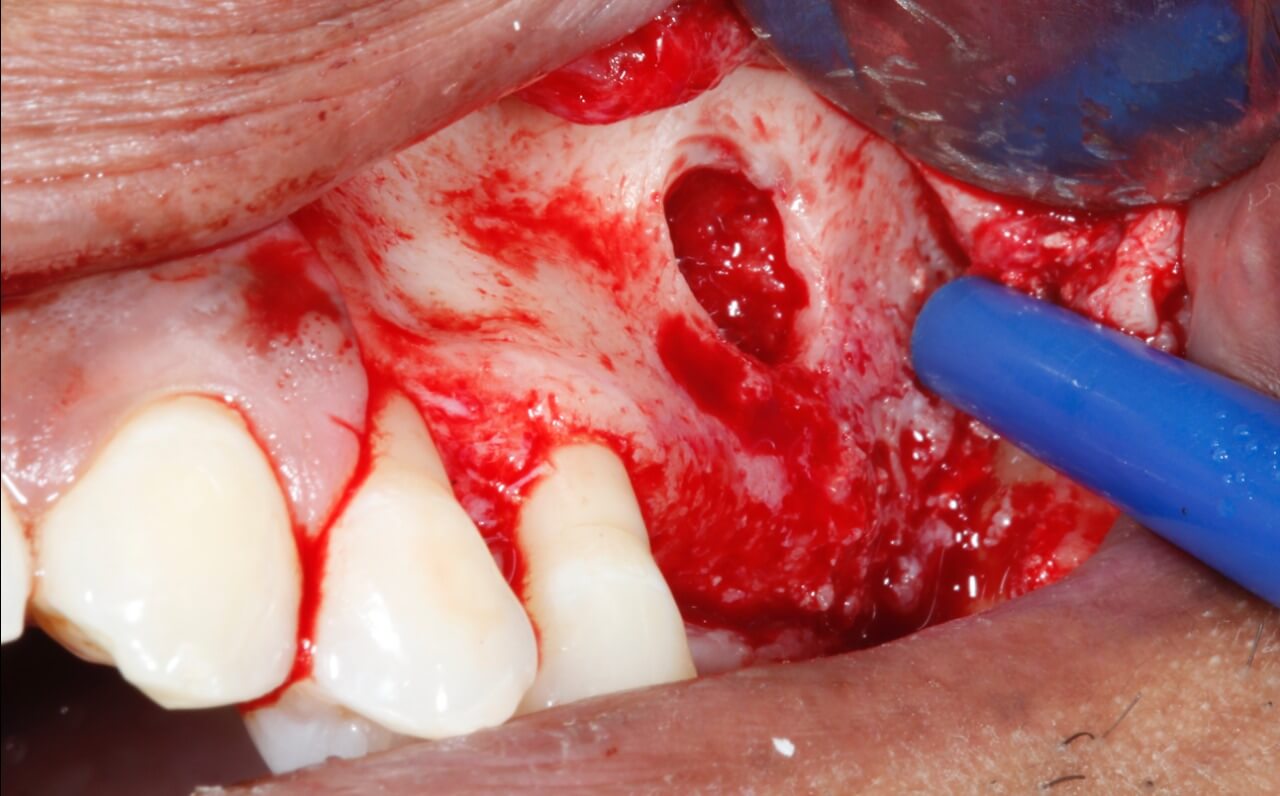

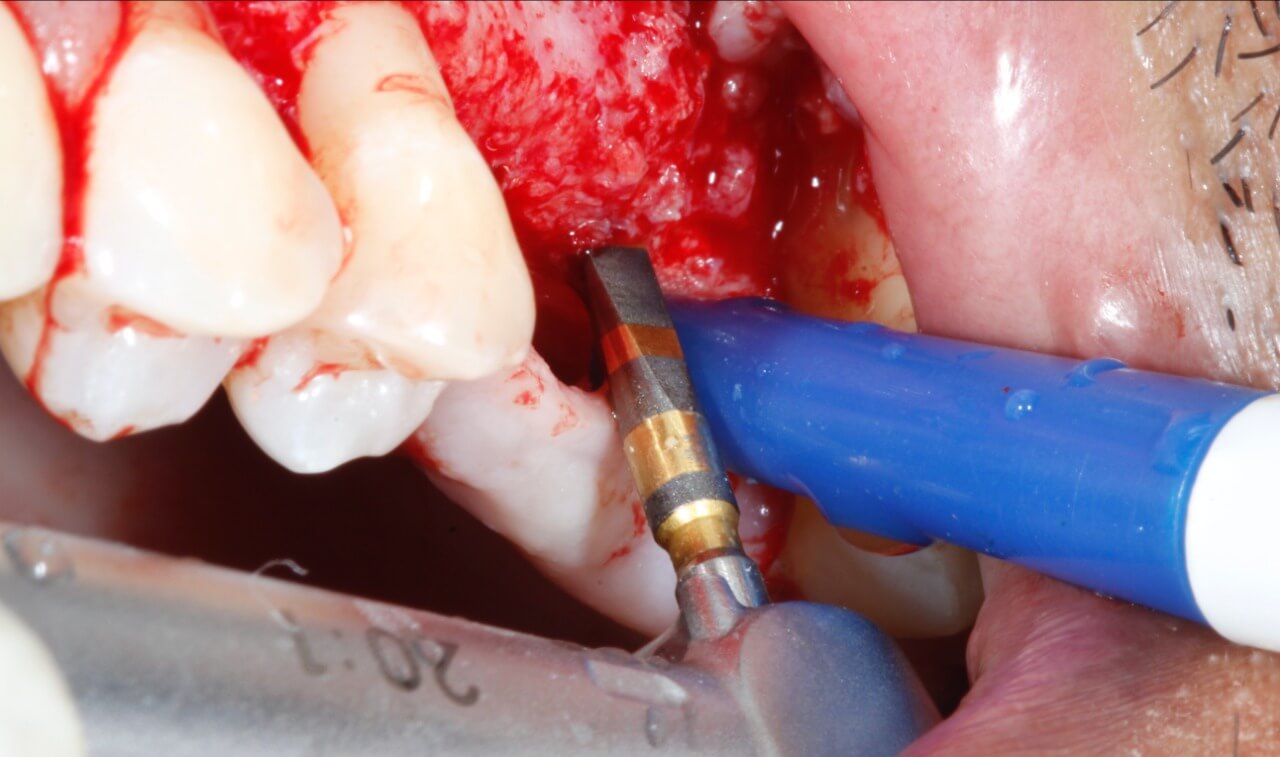

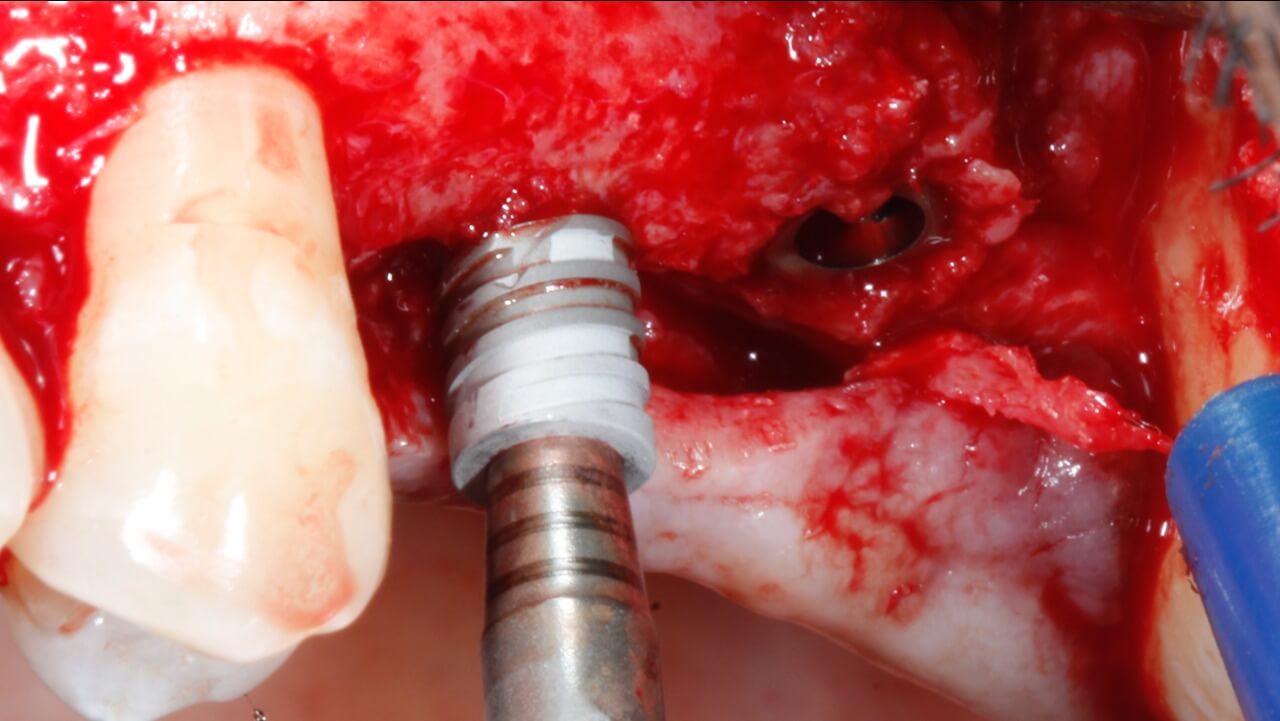

Since the tomographic exam showed 6.79mm and 6.29mm remaining bone of the areas of elements 26 and 27 respectively (fig. 1), the plan made was to apply the surgical technique to lift the maxillary sinus SA3 described by Carl Misch et al. According to that technique, the lifting of the maxillary sinus floor is carried out at the same time of the installation of dental implants. In order to have access to the maxillary sinus, we used a neurologic mill (Fig. 2), with the purpose of achieving more preciseness in the osteotomy (Fig. 3).

Working in a surgical site with low density and knowing that the geometry of the mills allows for single drilling, we chose that technique for the perforation of the surgical sites (Fig. 4). The tridimensional positioning of the implants must be perfect and, therefore, it is important to carry out an adequate reverse planning, working with a surgical guide and, in the trans-operatory phase, always verify parallelism, using the posts appropriate for that function (Fig.5).

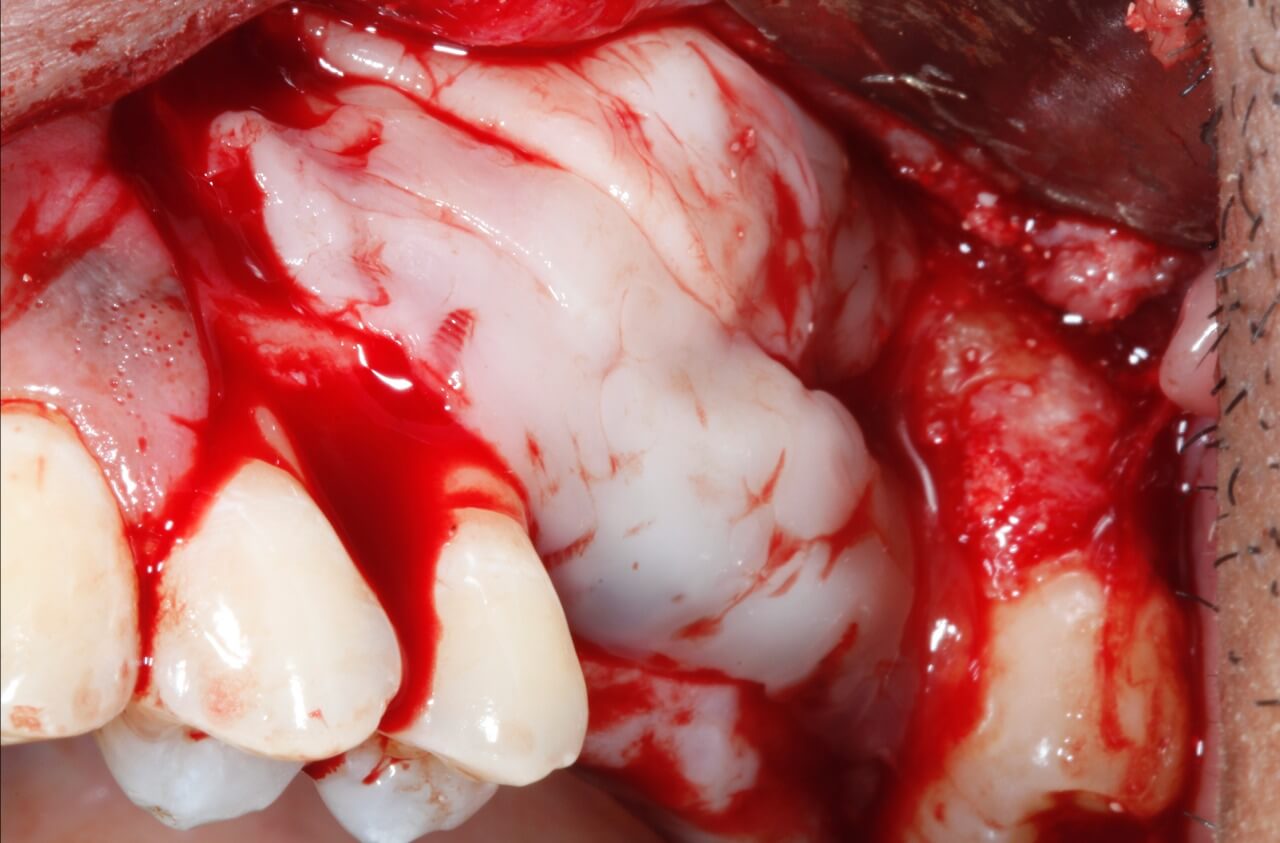

Afterwards, the L-PRF BLOCK was carried out associating FGM’s Nanosynt with particle granulations between 500 and 1000µ to the platelet aggregate, inserting it to the maxillary sinus (Fig. 6). Following that, implants were installed in the surgical sites and L-PRF membranes were inserted in the lateral wall of the maxillary sinus before suture (Fig. 7 and 8).

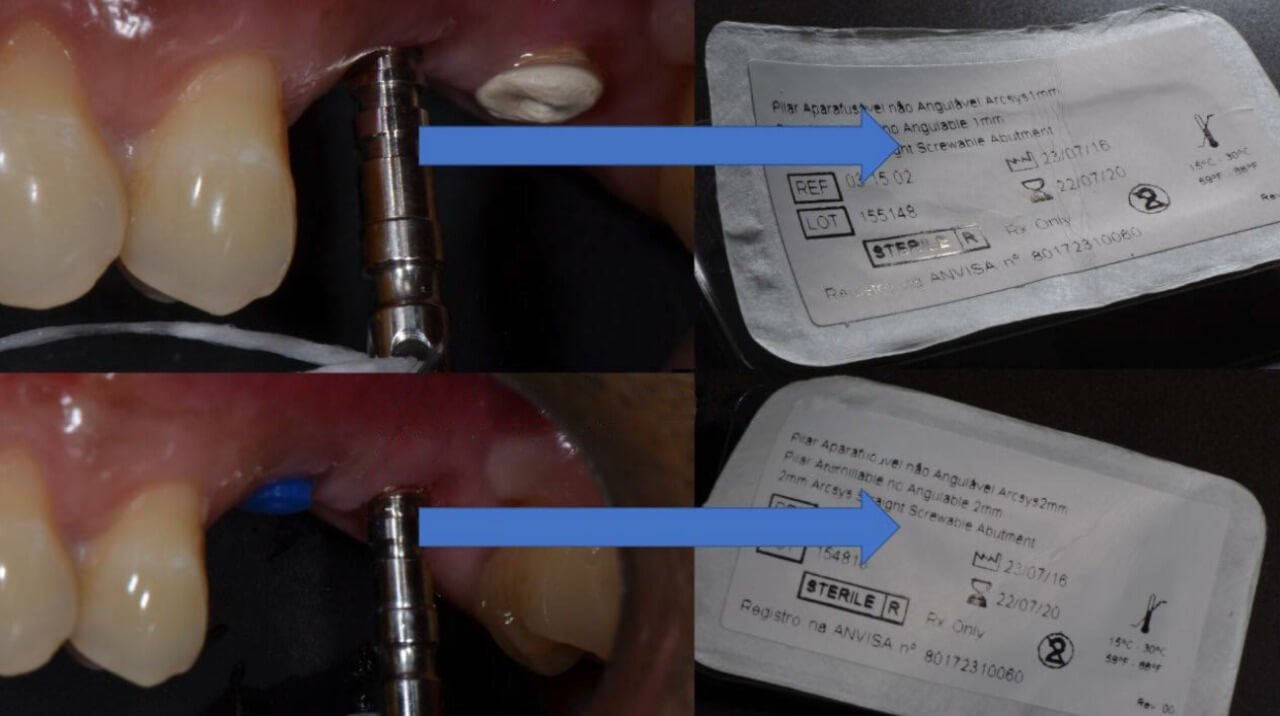

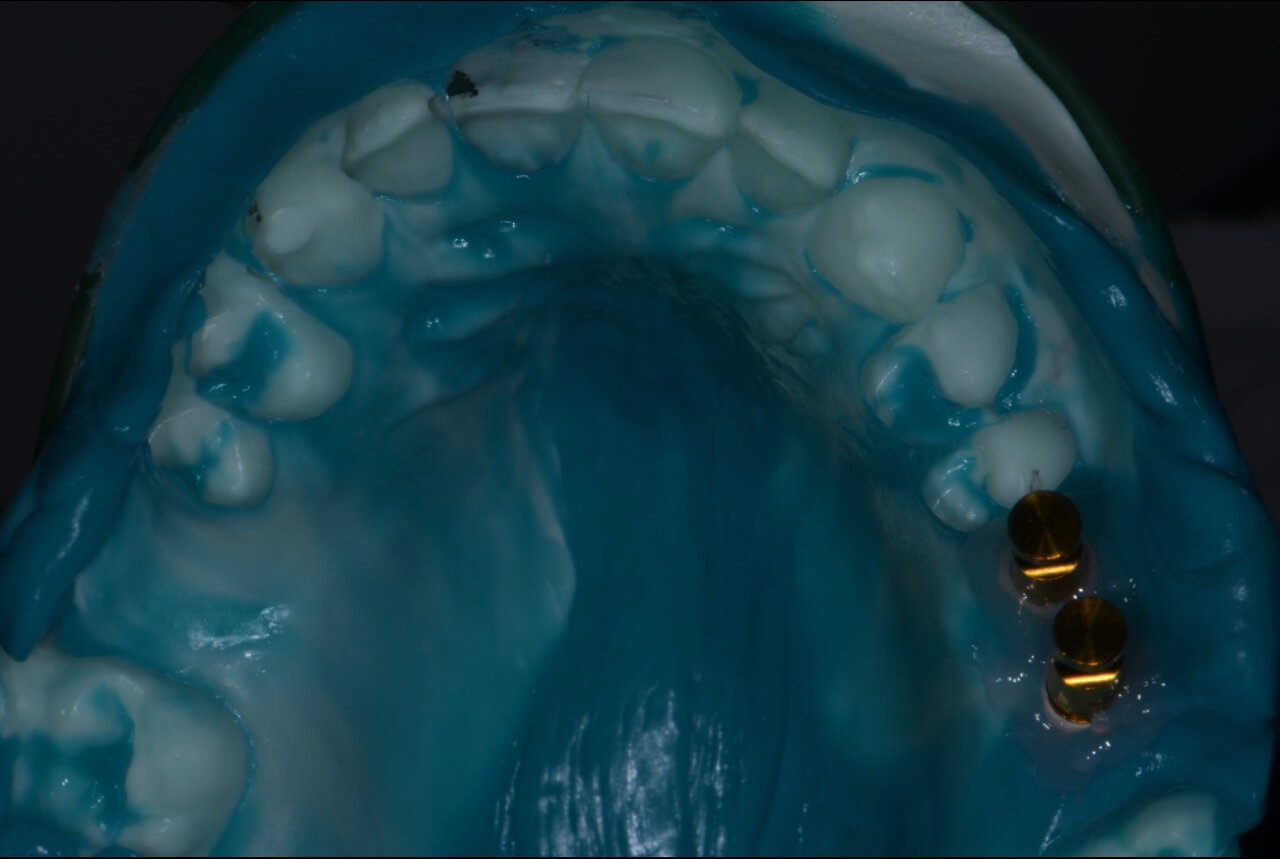

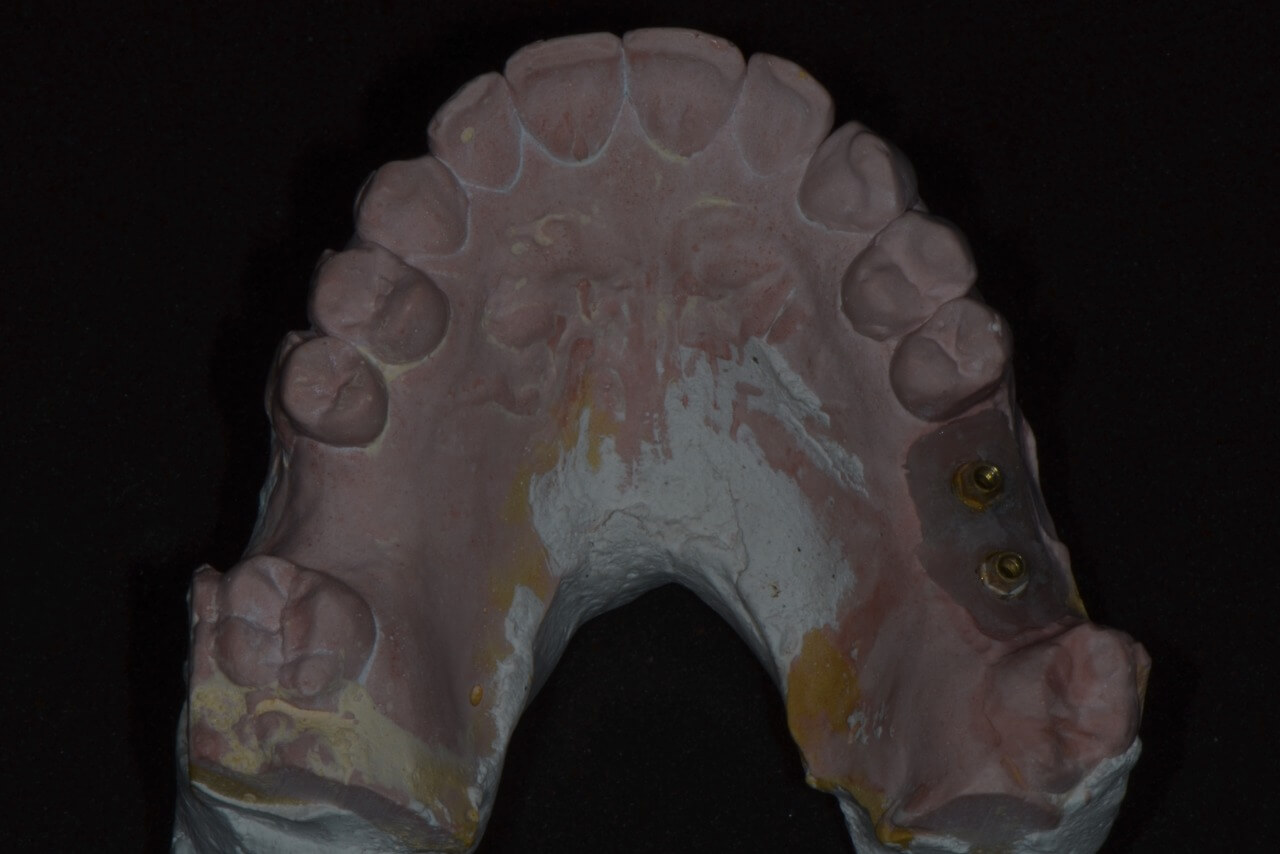

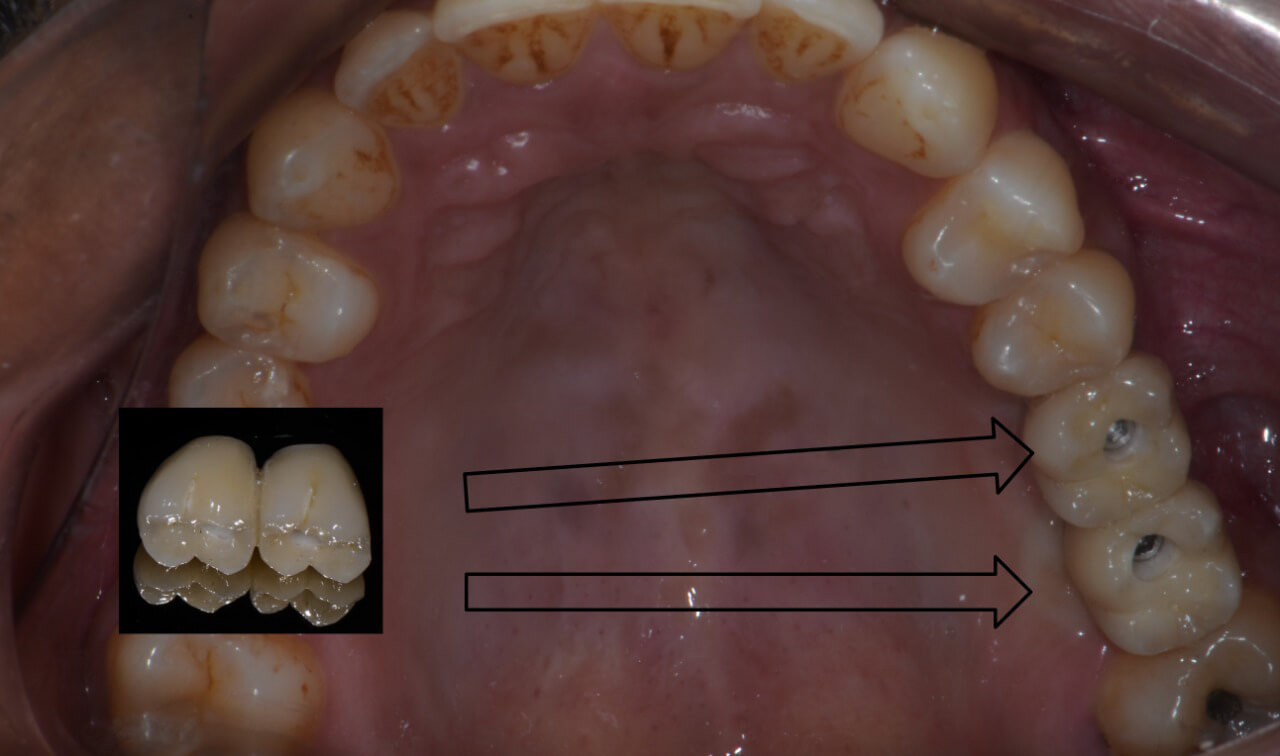

4 months later, the healing abutments were removed (Fig. 9) and the transmucosal measurer was positioned to select the mini abutments (Fig. 10). Then, those intermediate abutments were installed using the abutment placement tool (Fig. 11). Molding was then carried out (Fig. 12) and the plaster was applied (Fig. 13) and sent to the laboratory. In the laboratory, the plaster model was converted to a digital model, transferring the position of the implants by means of the Arcsys scan body, followed by a digital flow for the manufacture of the crowns over implants (Fig. 14). The crowns were finalized and installed over the implants (Fig. 15).

![levantamento de seio - Maxilary sinus lift with the concomitant installation of implants: clinical case report levantamento-de-seio-maxilar[1]](https://fgmdentalgroup.com/wp-content/uploads/2022/11/levantamento-de-seio-maxilar1.jpg)